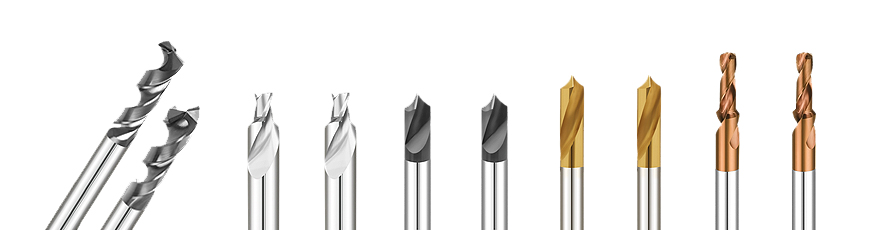

Scaling chisels work in rotary hammers or hammer drills for chiseling, scaling and chipping masonry.ĭepth stops prevent drilling beyond a predetermined depth.ĭriver bits and bit holders work on a drill / driver to install or remove fasteners. They allow you drill angled holes that accept screws for making wood joints. Pocket hole bits are stepped-diameter bits included with pocket hole jigs. In addition to more common drill bits, there are other options and accessories:ĭrill saw bits cut irregular holes and contours in wood and metal. The bit can move forward and backward with the hammering motion of the drill while flattened areas and slots on the shank allow the chuck to hold the bit. An SDS (slotted drive system) shank is designed for use on a hammer drill it fits a spring-loaded chuck that doesn’t require tightening.Hex shanks such as the one in the image above work with quick-change chucks — common on cordless drills — allowing you to insert and remove them without tightening and loosening the chuck. A hex shank has flat surfaces, allowing the tool to grip the bit more securely for greater torque.A round shank allows you accurately center a bit in the chuck.A larger bit may have a reduced shank — a shank with a smaller diameter than the body of the bit — allowing you to use it with smaller chucks. The bit shank size must not exceed the chuck size of the drill. Drill presses also have larger chucks — 1/2-inch or 5/8-inch, for example. A smaller drill for work around the house typically has a 3/8-inch chuck. More powerful drills for heavier applications have a larger, 1/2-inch chuck. The chuck on a hand drill or drill press secures a drill bit to the tool along the bit’s shank. You can add larger bits – 5/16 inch, 3/8 inch, 7/16 inch and 1/2 inch bits if you need them. Some projects call for specific drill bit sizes, but a set that includes bits from 1/16 inch to 1/4 inch will handle many jobs around the home and workshop. Bits with split-point tips improve drilling accuracy by keeping the bit from wandering when you begin to drill.īit size reflects the diameter of the body. They stay on center better and produce cleaner entry and exit holes. Bits with steeper points — such as those with 118-degree angles — are suited for softer material. They may require a pilot hole to keep the bit from wandering. Flatter points — such as those with 135-degree angles — are suited for drilling into harder material. They’re effective for drilling tile and masonry.įor a typical drill bit, the angle of the point helps determine what type of material the bit can drill. Carbide-tipped bits stay sharp much longer than steel, HSS or titanium bits.They work for drilling wood, metal, fiberglass and PVC. They’re tougher than basic HSS bits and stay sharp longer. Titanium-coated HSS bits produce less friction.They last longer than basic HSS bits and work well on a variety of materials, including metal, hardwood, softwood, PVC and fiberglass. Black oxide-coated HSS bits have a finish designed to help resist corrosion and increase durability.They’re mostly used for boring in aluminum and tough metals such as stainless steel. Cobalt bits are extremely hard and dissipate heat quickly.They can drill wood, fiberglass, PVC (polyvinyl chloride) and soft metals such as aluminum. They resist heat better and stay sharp longer. High-Speed Steel (HSS) bits are harder than steel bits.Steel bits work well for boring in softwood, but dull quickly in hardwood.The materials from which bits are manufactured and the finishes applied to them play a significant role in the life and performance of the bit. This is a summery of how to choose the proper drill bit:

0 kommentar(er)

0 kommentar(er)